Technical characteristics

Forklift motors are mainly used in electric forklifts, electric trucks, electric tractors, golf carts, tourist vehicles, electric vehicles and other vehicles powered by batteries, including traction motors, pump motors and power steering motors. This series of motors have many advantages such as wide speed range, large overload capacity, high mechanical strength, stable operation and so on, and can meet a variety of working conditions such as heavy-load starting, full-load climbing and high-speed operation of flat roads.

The motor can run normally under the following conditions: the ambient air temperature does not exceed 45 ℃; the relative humidity does not exceed 90% (20 ℃); the altitude does not exceed 1000m.

The battery voltage that can be used for the motor is 24V, 48V, 72V. AC rated voltage and rated frequency can be designed as required.

The standard working system of the motor is S2-30min or S2-60bmin.

1. Protection level: The protection level of the motor is IP20 (open type) or IP44 (closed type).

2. Cooling method: The cooling method of the motor is IC410 (natural cooling) or IC411 (self-fan cooling).

3. Structure and installation type: The motor can be installed vertically or horizontally, and the shaft extension type is cylindrical, conical, internal spline, and external spline.

4. Insulation class: The motor adopts H class insulation, which effectively improves the service life of the motor.

5. The stator adopts VPI vacuum pressure dipping paint process, which improves the overall insulation capacity and mechanical strength.

6. The rotor is specially designed to improve efficiency and torque.

7. The encoder uses SKF bearing built-in encoder or external encoder.

8. The temperature measuring components are imported KTY84 series products.

9. The brake can be configured as required.

Technical Parameters

|

Model |

Power |

Voltage |

Electric current |

Power factor |

Frequency |

Rotating speed |

Rated torque |

Max torque |

Effectiveness |

Noise |

Vibration |

Encoder / pulse |

|

GP0.75-90S-4 |

0.75 |

16 |

43 |

0.75 |

89.9 |

2600 |

2.75 |

34.2 |

79.7 |

60.0 |

0.8 |

48/32 |

|

GP1.2-90S-4 |

1.2 |

23 |

43 |

0.81 |

79.1 |

2270 |

5.05 |

48.3 |

79.7 |

80.0 |

1.2 |

48/32 |

|

GP1.5-90L-4 |

1.5 |

16 |

76 |

0.83 |

88.9 |

2590 |

5.53 |

20.9 |

81.1 |

61.0 |

1.0 |

48/32 |

|

GP2.0-90L-4 |

2.0 |

16 |

100 |

0.82 |

115.2 |

3362 |

5.68 |

27.2 |

80.4 |

61.5 |

1.1 |

32 |

|

GP2.5-90L-4 |

2.5 |

16 |

120 |

0.85 |

116.2 |

3352 |

7.12 |

29.3 |

80.7 |

61.5 |

1.5 |

32 |

|

GGP3.0-100S-4 |

3.0 |

33 |

73 |

0.81 |

89.4 |

2638 |

10.86 |

69.3 |

92.5 |

61.0 |

1.3 |

64/32 |

|

GGP4.0-100S-4 |

4.0 |

33 |

95 |

0.77 |

87.6 |

2580 |

14.81 |

58.5 |

89.2 |

60.5 |

1.4 |

64/32 |

|

GGP4.0-100L-4 |

4.0 |

51 |

57 |

0.79 |

123.9 |

3680 |

10.38 |

77.6 |

89.2 |

60.5 |

1.5 |

64/32 |

|

GGP5.0-100L-4 |

5.0 |

51 |

78 |

0.81 |

112.7 |

3332 |

14.33 |

78.9 |

89.4 |

61.0 |

1.3 |

64 |

|

GGP5.0-100L-4 |

5.0 |

33 |

113 |

0.87 |

119.3 |

3520 |

13.57 |

54.3 |

89.0 |

61.5 |

1.6 |

64 |

|

GGP4.0-112S-4 |

4.0 |

33 |

95 |

0.88 |

60.0 |

1710 |

22.34 |

118.2 |

84.1 |

60.0 |

0.7 |

64/32 |

|

GGP7.0-112L-4 |

7.0 |

51 |

102 |

0.89 |

104.4 |

3065 |

21.81 |

110.5 |

85.4 |

63.2 |

1.2 |

64 |

|

GGP9.0-132S-4 |

9.0 |

51 |

135 |

0.88 |

52.8 |

1444 |

59.52 |

140.5 |

84.0 |

64.3 |

1.2 |

32 |

|

GGP11-132L-4 |

11 |

51 |

158 |

0.89 |

80.0 |

2237 |

46.96 |

158.0 |

82.4 |

68.1 |

1.5 |

32 |

|

GGP13-160S-4 |

13 |

51 |

175 |

0.88 |

80.0 |

2308 |

53.80 |

172.4 |

86.0 |

69.2 |

1.6 |

32 |

|

GGP15-160L-4 |

15 |

51 |

192 |

0.89 |

85.0 |

2550 |

56.20 |

190.5 |

87.0 |

69.8 |

1.6 |

3 |

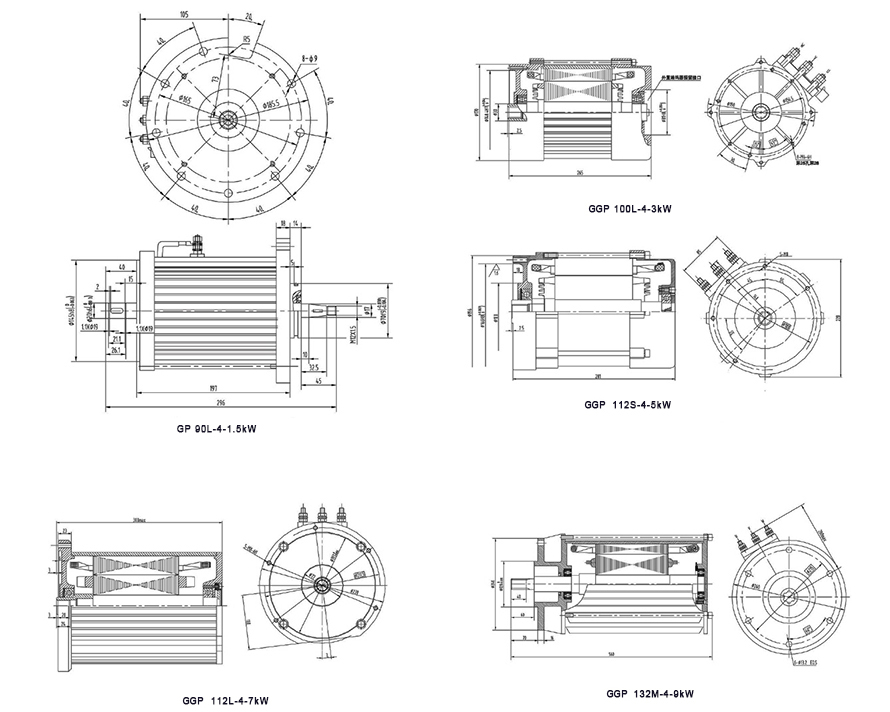

Installation dimensions